Product Development

We constantly strive to develop latest techniques to ensure only the best products are manufactured

Market Analysis

We believe in following the latest Industry & market trends to provide the latest solution.

Client Management

Our customers are at the forefront. We pride in associating closely with our clients & offer latest innovations with class leading quality assurance.

Why choose us?

Quality assurance and customer centric approach lead us in the industry and enables us the energy to manufacture highly promising, innovative and quality products at effective.

- Advanced equipments and stringent quality measurement.

- Commitment to hygiene and cleanliness ensures food grade FIBCs that are sanitised and free from dust, germs and pollutants.

- Integrate suitable techniques for quality improvement.

About our Company

We believe in stepping and attaining an extra mile when it comes to quality of everything we do. Continual efforts of quality improvement and commitment to comply with international quality norms won us customers all over the globe. Innovative products, unmatched quality and dedicated support services.

Products

We offer a wide range of options when it comes to FIBC.

With attention to detail, and proper understanding of what our customers demand,

rest assured the quality and options one has with BagPacks is wide.

Standard and UN FIBCs

Coated or uncoaated sheet with and without dust proofing. Available with various filling, unloading and hoisting systems. with proper UN quidelines.

Baffle/Formstable FIBC

These FIBCs (O/Baffle bags) have been specially developed for improved stability and a more efficiend load volume. Saves transport costs.

Ventilated FIBC

FIBCs used for transporting cargoes requiring ventilation and breathability like vegetables, etc.

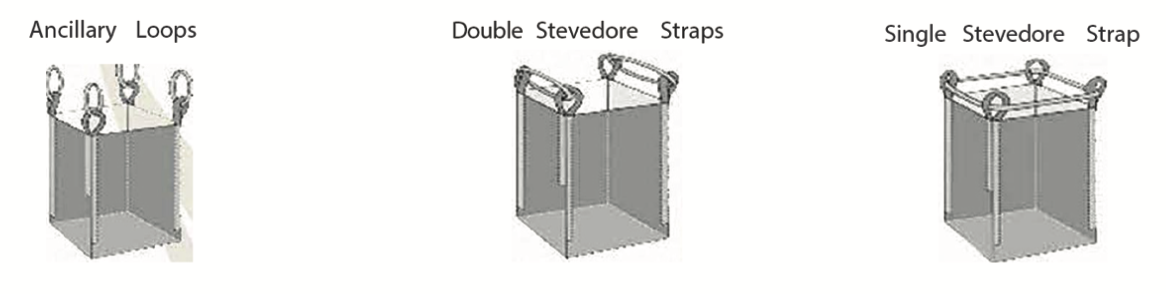

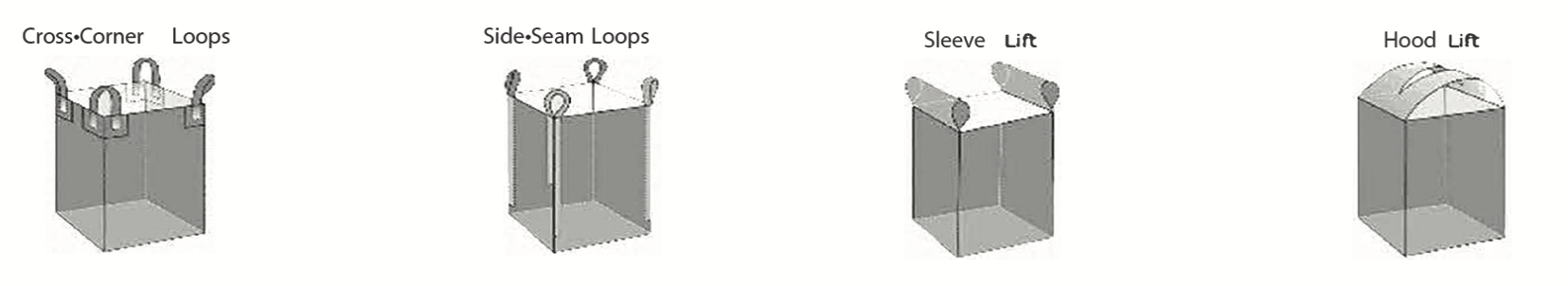

Loop types

Our various offerings

FIBC - Buffle Bags

A standard FIBC bag which is filled to capacity with material to be stored or transported tends to bulge a lot. Baffle bags have baffles which are basically panels of fabric on each side of the bag which do not allow it to get out of shape even when full. Both Baffle and Standard FIBCs are used for different materials.

PP Woven Sacks / Small Bags

Woven PP bags are laminated with a polypropylene coating, inside or outside, giving an added barrier to moisture and product leakage, without hindering Easy- Open and Re-Closure options. They are also UV stabilised for a longer lifespan when exposed to sunlight. These sacks allow sufficient passage of air to the packed items and ensure the phenomenon of "breathing space in packed grains. They can also be laminated for the moisture proof packing of different items. Features Fabric weight from 65 qsm to 200 gsm, Extrusion coated and uncoated versions 10 x10, 10 x 8, 12 x 12 and 14 x 14 weave construction, Multi-color printing, Ultraviolet (UV) protection Common products packaged in woven PP bags are: Salt, Coal, Flour, Sand, Fertilizer, Pet Food, Feed and Seed, Cement / Aggregate, Chemicals, Powders, Rice Grains, Beans.

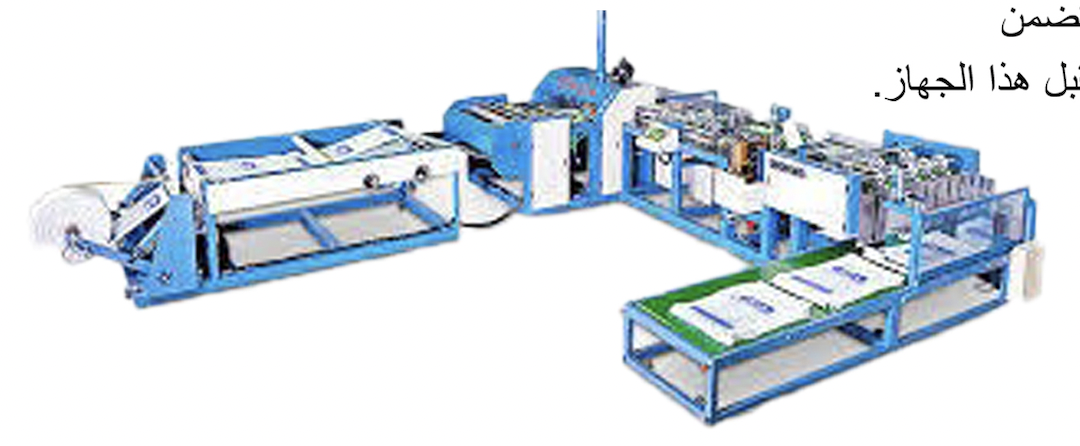

Small Bag Sewing Machine

We come equipped with the best Small Bag Sewing machine with variable stiching and finish options for our customers. The machine ensures the quality and finish of the end product is always at the best Industry Standards and complies with the international norms. Strong, Sturdy Construction of PPE materials is essential quality of bags manufactured by this machine.